Blackpearlnite ブラシクパールナイト

ARE THESE SCENARIO SOUND FAMILIAR?

- Shocking Mold & Die material spending in month end?

- O. E. E. couldn't achieve due to 6 Big Losses?

- Spending in tooling doesn't bring significant return?

- Troublesome in Mold & Die inventory management?

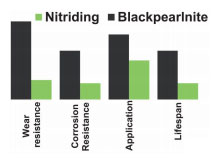

ブラシクパールナイト Blackpearlnite vs Nitriding

Revolution in surface finishing which brought us a 10 years leaps in relevant industries. Blackpearlnite consolidate advantages from conventional Nitriding process and Coating (PVD/CVD/TD).

Characteristic included:

Characteristic included:

- High Precision, < 2μm changes

- Lower Coefficient of friction

- Lower Cost compare to Coating

- Strong Wear Resistance

- Erosion & Heat Check Resisance

- Corrosion Resistance, >400hr S.S.T.

- High Thermal Resistance

- Lubricant Free

- Fatigue Resistance

- Shorter Delivery Lead Time

- Wide Range of Application

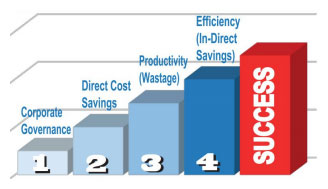

Investing in ブラシクパールナイト Blackpearlnite and get return:

- Eliminate 6 BIG LOSSES, achieving world class O.E.E.

- 70% saving in RAW MATERIAL.

- 50% saving in PROCESSING & MISCELLANEOUS.

- Realization of K.P.I. target in short term(1~3 MONTHS).

- Tooling failure isn't a valid escuse anymore.

Advantages

-

Free Release Agent

Due to its erosion resistance, heat resistence and releasability are higher than ceramic coating, it does not react with molten metal or solid metal. Therefore, it has better heat checking resistance as compared to nitriding treatment.

-

Low Temperature Treatment

Due to lower temperature treatment as compared to tool steel’s tempering temperature, there is no deformation or distortion in dimensions.

-

Uniform Treatment to Complex Shaped Product

Unlike conventional PVD coating, Blackpearlnite can heat treat various 3-D solid complex shapes with deep holes, narrow slits and therefore it has wide range of applications.

-

Applicable to Large Scale Prod

It can heat treat small pin to 1 ton (depends on furnace size)

-

Low Cost

Heat treatment cost is relatively cheaper than conventional PVD, CVD and TD method.

-

Shorter Delivery Leadtime

Heat treatment cost is relatively cheaper than conventional PVD, CVD and TD method.

APPLICATION

- Gravity casting mold (Aluminium)

- Low pressure casting mold ( Aluminium)

- Machine parts for casting: Puncher, Sleeve, Chip,

- Gooseneck, etc)

- Die casting mold (Aluminium, zinc, Magnesium)

- Magnetic Mold

- Hot & warm forging mold (ferrous, Aluminium etc)

- Aluminium extrusion die

- Various mechanical parts which requires erosion

- resistance, wear resistance, fatigue resistance.

APPLICATION FINDINGS/ RESULT

Aluminium Die Cast Mold- Molten: ADC12 (680 C)

- Mold Material: SKD61

- Automotive Parts

| Effect | |

| Gas Nitriding | Blackpearlnite |

| 28,000 shots and beyond: Mold damage due to erosion and thermal fatigue. | At 100,000 shots: erosion, thermal fatigue or heat checking has not occur |

- Molten: AC8D (850 C)

- Rotor Material: FCD250

- Product: Diesel Engine Piston

| Effect | |

| Before Heat Treatment | Blackpearlnite |

| 10 days after lubrication, erosion damage found on rotor | 1 month after lubrication, erosion damage is visible.(lifecycle is 3 times longer) |